카트는 현재 비어 있습니다..

Still troubled by stubborn contaminants like rust, paint, and industrial coatings? Are you stuck with issues such as environmental pollution from chemical cleaners, substrate damage from traditional grinding, and low cleaning efficiency? The emergence of pulsed laser cleaning technology has completely changed the game-with its core advantages of non-contact operation, precision, and environmental friendliness, it vaporizes contaminants using light energy, achieving efficient cleaning while perfectly preserving the integrity of the substrate. This article is tailored for beginners, comprehensively dissecting the working secrets of pulsed laser cleaners from technology definition, core configurations, physical principles to practical steps, helping you quickly master this advanced cleaning technology.

Pulsed laser cleaning is a new type of cleaning technology based on high-energy focused laser beams. Its core lies in emitting ultra-short pulsed lasers to precisely act on the surface of contaminants and remove them. Each laser pulse lasts only nanoseconds (one billionth of a second), but despite its extremely short duration, it contains enormous peak energy, which can rapidly heat contaminants such as rust, paint, oxides, and oil stains.

The key advantage of this technology is "selective absorption": contaminants absorb laser energy much more efficiently than the clean substrate (e.g., metal) beneath. The system can emit thousands to tens of thousands of pulses per second onto the target surface. After absorbing the energy, contaminants quickly vaporize or peel off, while the substrate remains intact due to minimal heat absorption and low temperature. This fundamentally solves the pain point of substrate damage caused by traditional cleaning methods.

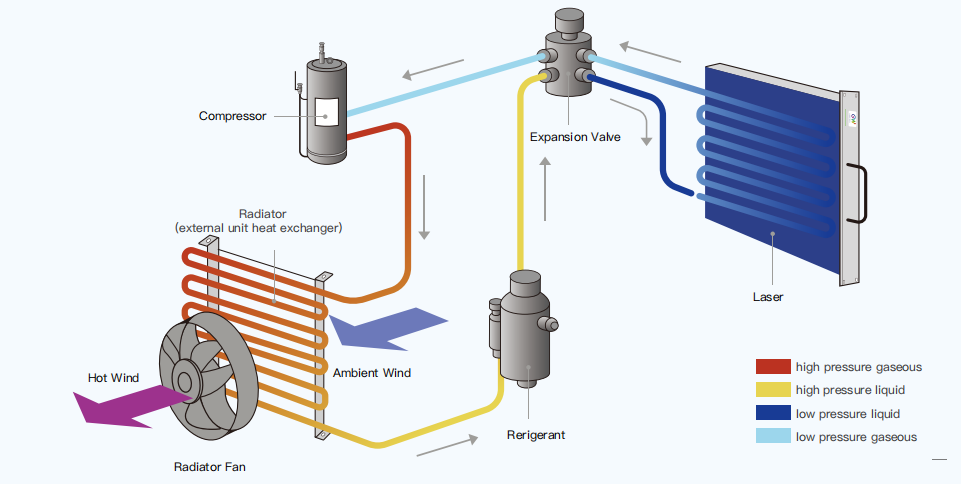

Industrial pulsed laser cleaners mostly adopt pulsed fiber lasers paired with a Master Oscillator Power Amplifier (MOPA) architecture, enabling precise control of laser output. They operate in the near-infrared wavelength range (approximately 1064-1070 nanometers), which highly matches the absorption characteristics of metals, ensuring cleaning efficiency and effectiveness.

The key operating parameters affecting cleaning performance are as follows:

The precise coordination of these parameters ultimately achieves the core advantage of "minimal heat input," effectively preventing the substrate from deformation, discoloration, or structural damage-this is also the key reason why pulsed laser cleaning outperforms traditional thermal cleaning methods.

The excellent performance of pulsed laser cleaning stems from the sophisticated collaboration of three basic physical principles. Unlike traditional methods that rely on brute force or strong chemicals, laser cleaning uses precise light energy to achieve superior cleaning results while protecting delicate substrates.

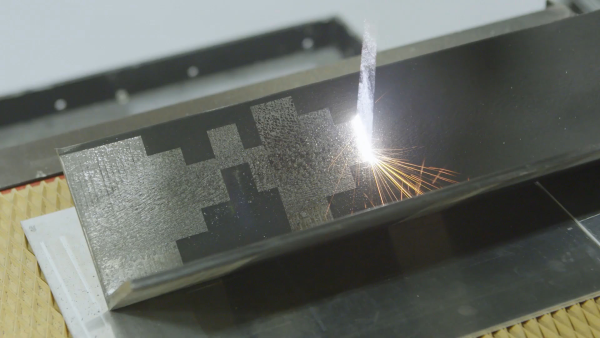

This is the core mechanism for removing stubborn contaminants such as heavy rust, thick paint, and industrial coatings. When high-energy laser pulses irradiate the surface, the contaminant layer absorbs the laser like a sponge-rapidly converting light energy into intense local heat. This causes the temperature to rise sharply, leading to instantaneous expansion and vaporization of contaminants, effectively blowing them away from the cooler underlying material. The process is extremely fast, and heat has no time to penetrate the substrate, thus preventing thermal damage.

This mechanism is crucial for delicate tasks-such as cleaning thin coatings, precision electronic components, or cultural relics. It works differently: ultra-short, high-power pulses deliver energy faster than the material can dissipate heat, directly breaking molecular bonds of contaminants into fine dust or gas in a controlled "cold" process. The temperature rise of the substrate is negligible, allowing it to maintain its original structure, hardness, and surface finish with micro-level precision.

Rapid vaporization generated by thermal ablation triggers a secondary effect: micro-shock waves, which can be regarded as small, controlled "explosions" at the laser impact points. These shock waves penetrate the contaminant layer, generating strong shear forces that mechanically peel off and remove any residual or loosely bound particles, resulting in a smoother surface with minimal residual debris and achieving deep purification.

The collaboration of these three mechanisms endows pulsed laser cleaning with the power of thermal energy, the precision of cold ablation, and the purification ability of shock waves. It can remove almost any surface contaminants without damaging the substrate, which is the core reason for its superior performance over traditional cleaning technologies.

Although pulsed laser cleaners integrate complex physical principles, they are extremely easy to operate. Beginners only need to follow the four steps below to complete efficient cleaning:

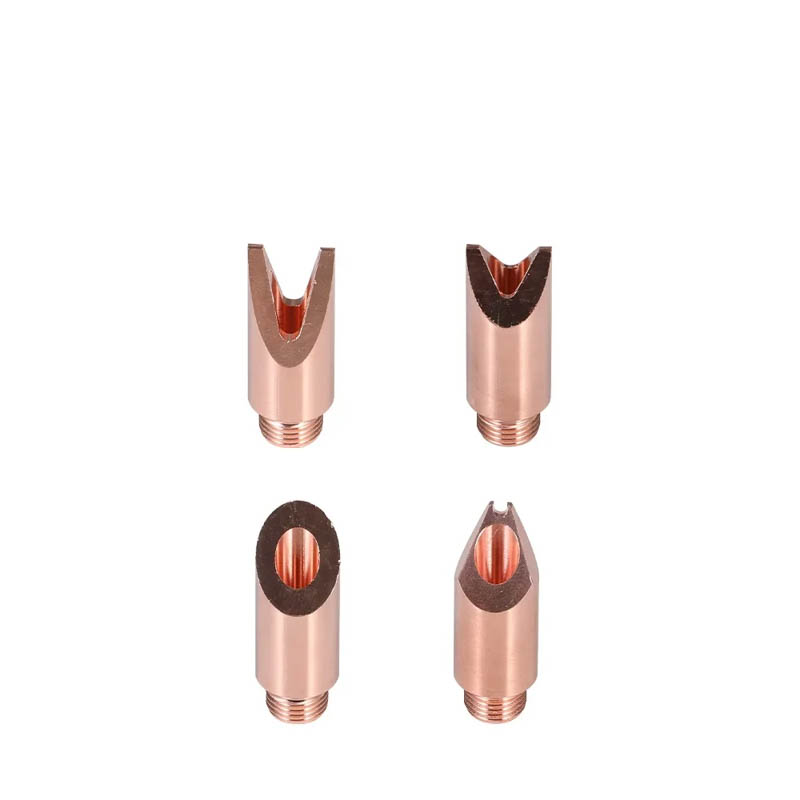

First, confirm the substrate type (e.g., steel, aluminum) and contaminant type (e.g., rust, paint). Based on this information, select the appropriate parameter preset from the machine interface. Then, aim the lightweight cleaning head at the target area.

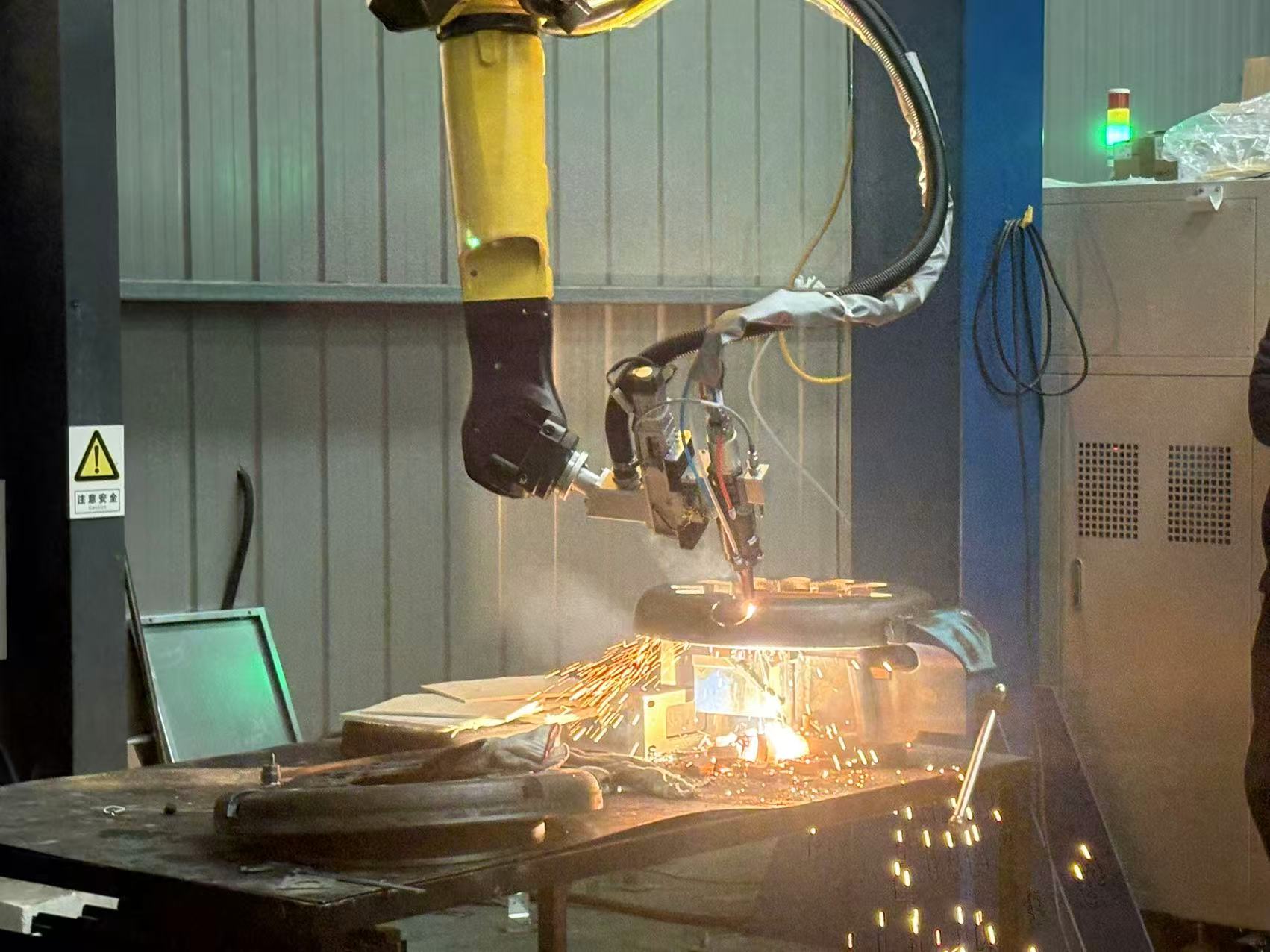

Press the safety start button. The laser begins emitting high-frequency pulses. Inside the cleaning head, a high-speed scanner instantly sweeps the laser beam across the surface at a speed of up to 35,000 millimeters per second according to a preset pattern (e.g., lines or grid). You guide the movement of the head, while the scanner handles precise, rapid beam scanning.

This is where the core scientific principles come into play. Contaminants (e.g., rust) absorb laser energy much more efficiently than the clean metal beneath. Using the principle of "selective absorption," the process removes dirt using light instead of external force or high temperature, causing the contaminant layer to instantly vaporize or turn into fine dust. The underlying material remains low-temperature and completely undamaged. The entire process is quiet, spark-free, and produces minimal, non-toxic dust.

Move the cleaning head to cover the entire area. After completion, you will get a restored surface-free of residues, scratches, and damage, often revealing the original surface texture.

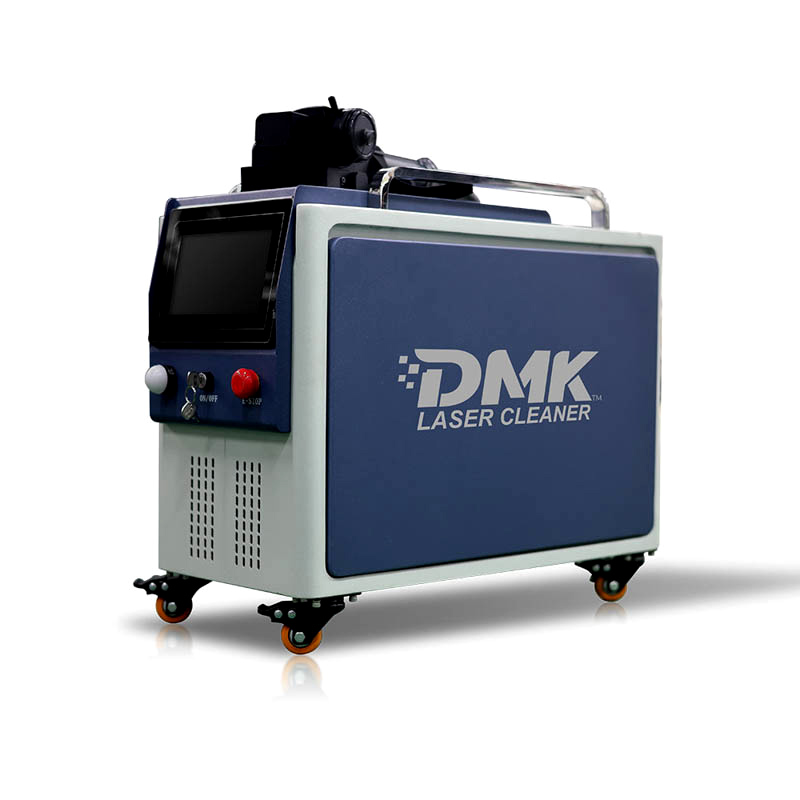

Understanding the principles of pulsed laser cleaning is just the beginning of exploring its powerful capabilities. It converts light energy into precise cleaning force, fundamentally avoiding environmental, health, and damage risks associated with traditional cleaning methods. From its lightweight ergonomic design, industry-leading scanning speed to intelligent cooling and control systems, an excellent laser cleaner is the key to transforming these principles into reliable, efficient production. Take the first step toward easy and precise cleaning-choose a laser cleaner designed for practical applications. Contact our team now for a free consultation.

Feb 5, 2026

카트는 현재 비어 있습니다..