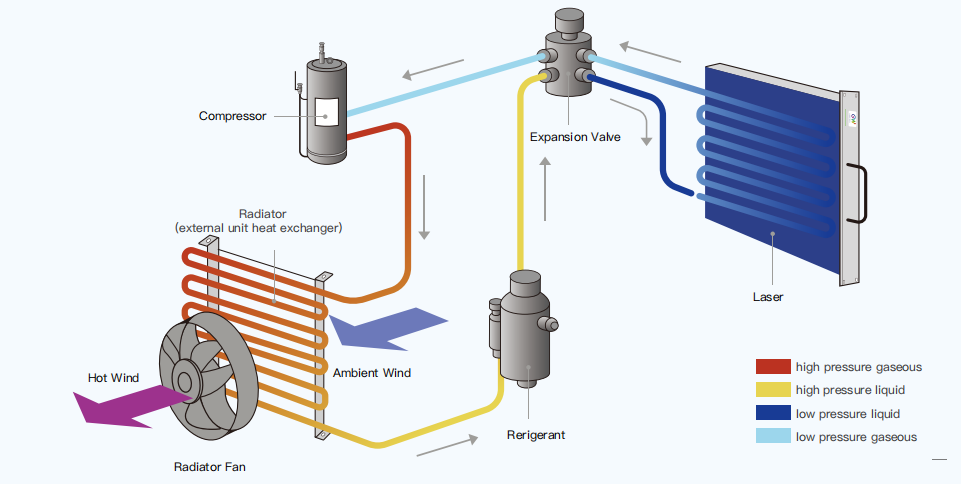

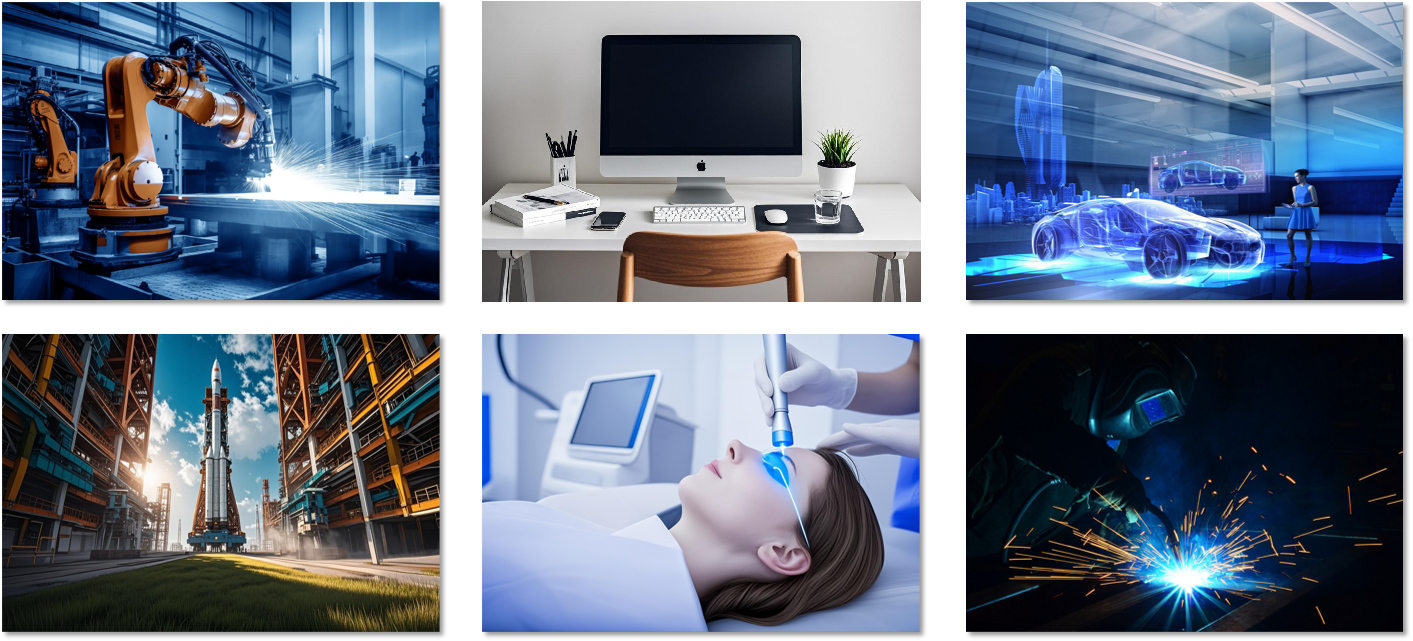

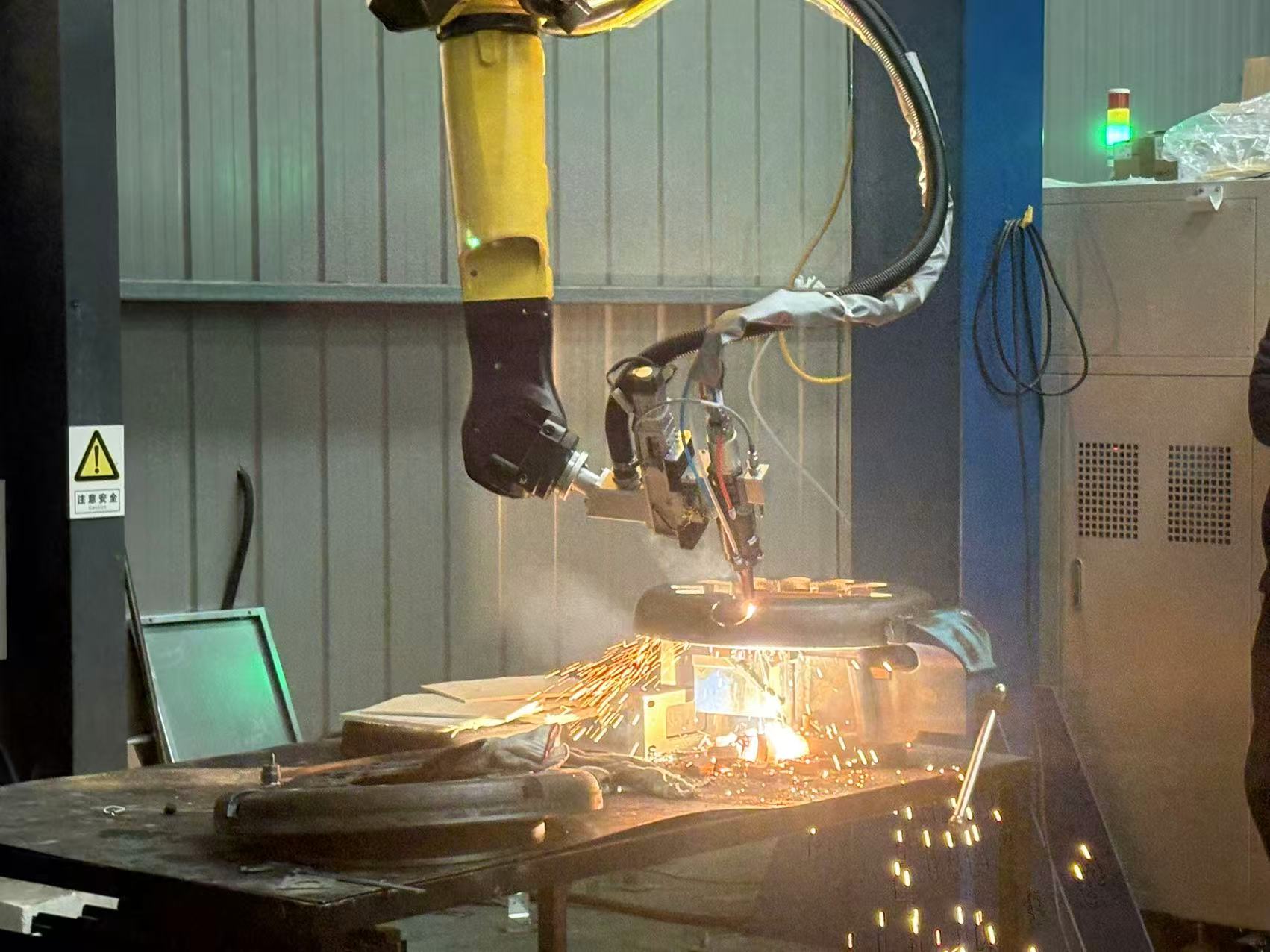

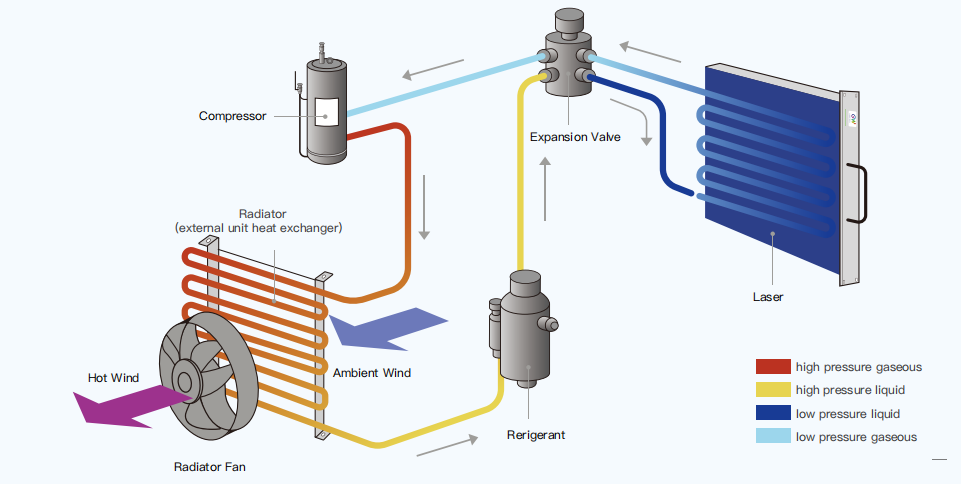

Low temperatures are an "invisible killer" for laser equipment! When the temperature drops below freezing, water in the cooling circuit freezes and expands—at best clogging pipelines, and at worst causing pipe bursts and optical cable damage, leading to costly repairs and prolonged production downtime. Proactively protecting the cooling system is key to ensuring the equipment survives the winter safely and operates stably. This article compiles core antifreeze points and maintenance tips to help you avoid low-temperature risks!

I. Antifreeze Usage: Core Steps for Low-Temperature Protection

1. Why Antifreeze is a Must

Antifreeze effectively lowers the freezing point of cooling water, preventing freezing and expansion from causing irreversible damage to pipelines and optical components—it’s a "protective barrier" in low-temperature environments.

2. Selection and Ratio: Precisely Match Local Temperatures

Recommend professional antifreeze (e.g., Clariant Antifrogen N, pale yellow liquid). Adjust the ratio according to the local minimum temperature to ensure antifreeze effectiveness:

| Local Minimum Temperature |

Antifreeze to Deionized Water Ratio |

| -42°C~-45°C |

6:4 (60% antifreeze + 40% water) |

| -32°C~-35°C |

1:1 (50% antifreeze + 50% water) |

| -22°C~-25°C |

4:6 (40% antifreeze + 60% water) |

| -12°C~-15°C |

3:7 (30% antifreeze + 70% water) |

3. Correct Addition Steps: Avoid Operational Mistakes

- Power off equipment: Turn off the power of all related equipment, including the water chiller and laser;

- Drain and clean: Open the water chiller’s drain valve to empty old water, rinse the water tank with water, and drain again;

- Clean filters: Remove, clean, and reinstall the water chiller’s filter element and the laser’s water inlet filter element;

- Mix and fill: Stir the prepared antifreeze and deionized water evenly in a container before pouring into the water chiller tank (never pour directly to avoid floc formation that clogs pipelines).

II. Key Notes: Avoid These Common Pitfalls

- Do not use antifreeze long-term. After the low-temperature season, thoroughly clean the water circuit and switch back to deionized water or distilled water;

- For long-term equipment shutdown (e.g., holidays), ensure all cooling water is drained, and blow residual moisture from the circuit with dry compressed air to eliminate freezing risks;

- Never use tap water or bottled purified water, as they may produce scale or breed microorganisms, clogging pipelines and affecting heat dissipation.

III. Routine Maintenance of Water Cooling Systems: Guarantee Year-Round Stability

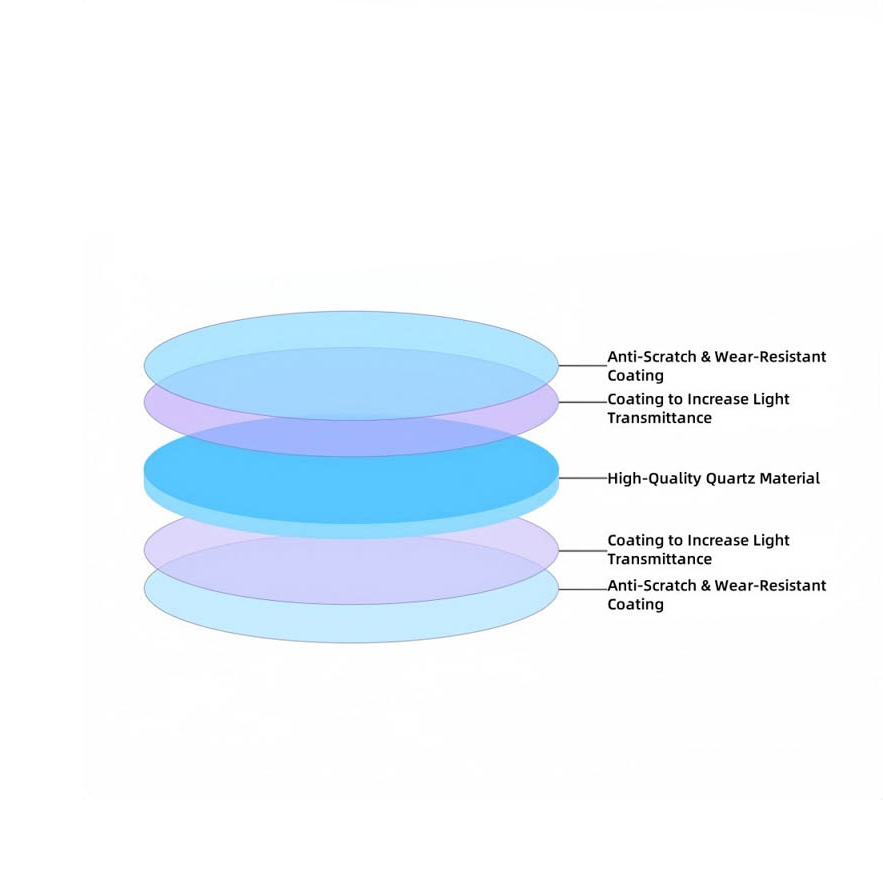

- Cooling water selection: Use only distilled water or deionized water to avoid impurities affecting the system;

- Replacement cycle: Replace cooling water every 3 months to prevent water deterioration;

- Antibacterial tip: Add 5%-10% alcohol to effectively inhibit bacterial and algae growth.

Conclusion

Low-temperature protection for laser coolant systems boils down to two key tasks: Add antifreeze in the correct ratio when temperatures drop below 0°C, and drain and dry the water circuit before long-term shutdown. Proactive protection avoids unnecessary losses and ensures year-round stable equipment operation. For further maintenance details, feel free to consult a professional technical team!