카트는 현재 비어 있습니다..

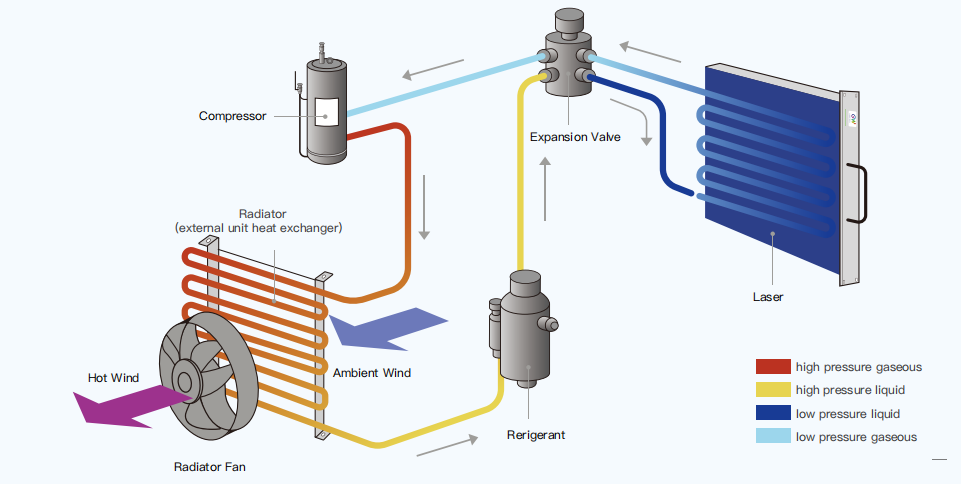

Copper, known for its excellent thermal and electrical conductivity, is widely used in electronics, automotive parts, and precision machinery. However, due to its high laser reflectivity (over 90%), laser welding copper presents unique challenges. This article explores recent advancements in copper laser welding using single-mode quasi-continuous fiber lasers, optimized welding parameters, and deformation control strategies.

Traditional copper welding methods, like resistance welding and soft soldering, have limitations. Resistance welding can damage surfaces, while soft soldering lacks strength. Laser welding, by contrast, provides strong atomic-level bonds with minimal surface damage due to its non-contact nature.

However, copper's high reflectivity causes significant energy loss during laser interaction, making it difficult to reach melting temperatures. Solutions like surface coatings or hybrid methods exist, but they add complexity and cost.

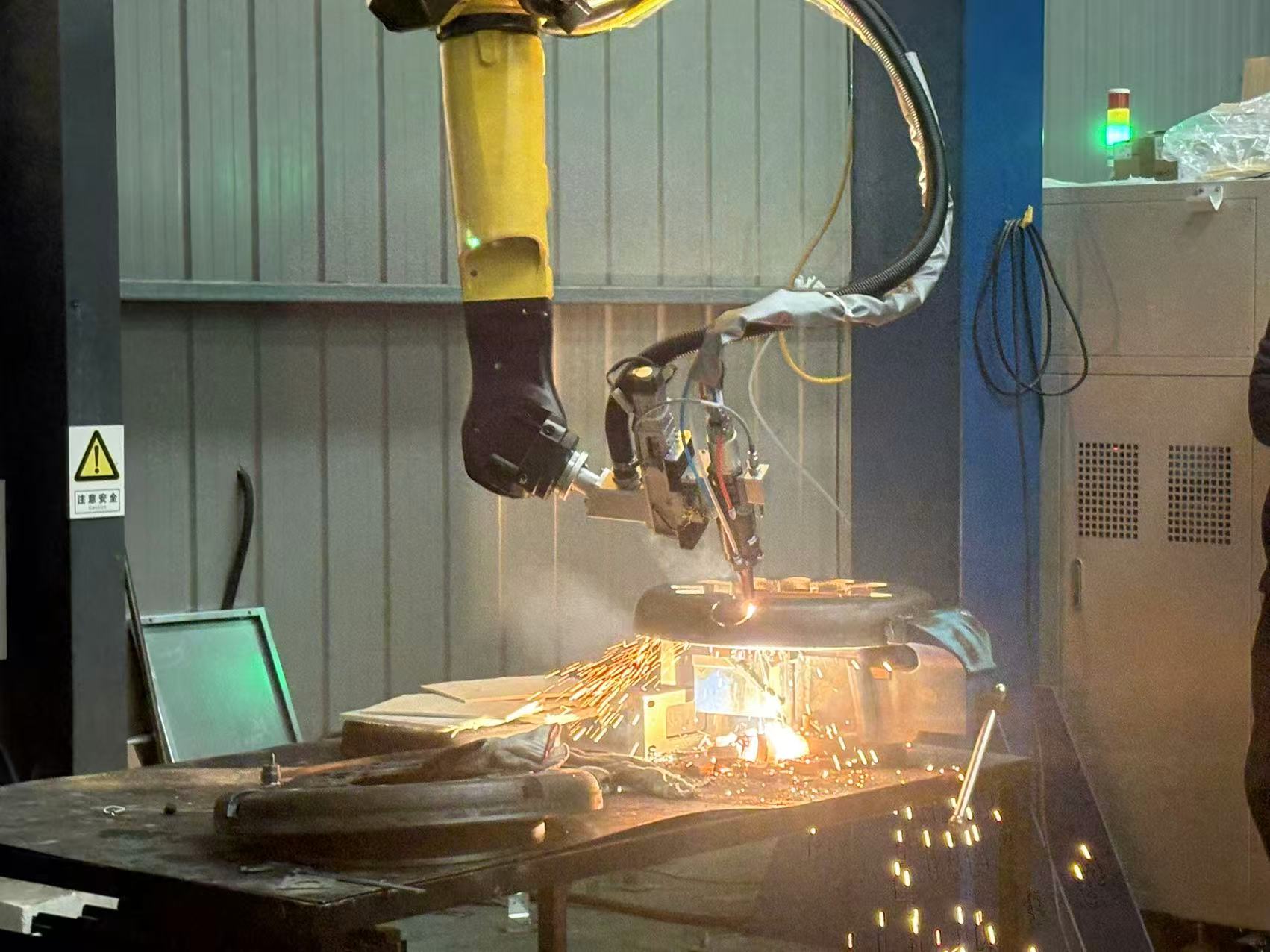

To address these issues, researchers used a YLR-150/1500-QCW single-mode quasi-continuous fiber laser, which offers excellent beam quality (M² ≈ 1.05), high peak power, and precise control.

Fig.1 Fiber laser

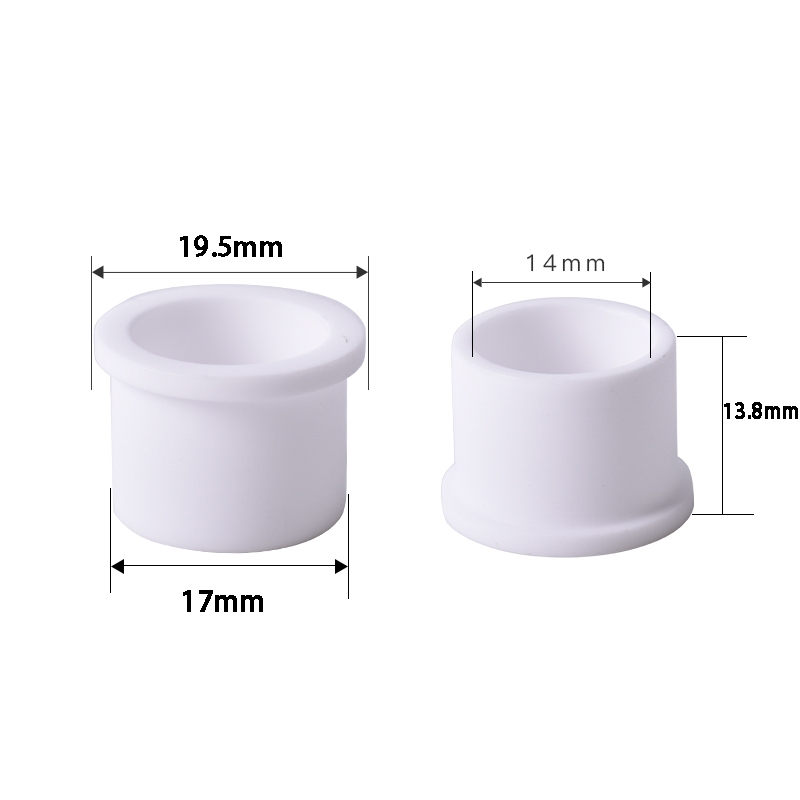

Material: Pure copper sheets (0.3 mm top layer, 0.1 mm bottom layer)

Welding area: 5 mm × 1 mm overlap joint

Testing: Post-welding tensile strength evaluation

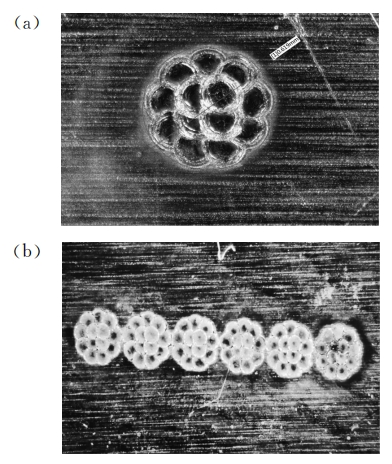

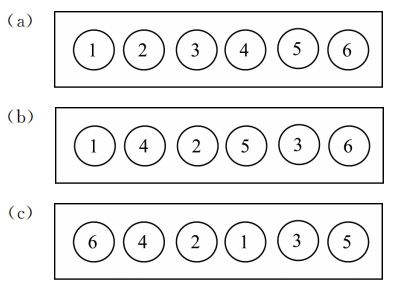

To overcome the issue of small single-spot melt zones (diameter 0.2–0.4 mm), multiple spots were arranged in clusters to increase the bonding area and improve strength.

Fig.2 Arrangement of welding spots

(a) Single solder joint arrangement diagram (b) Multiple solder joint arrangement diagram

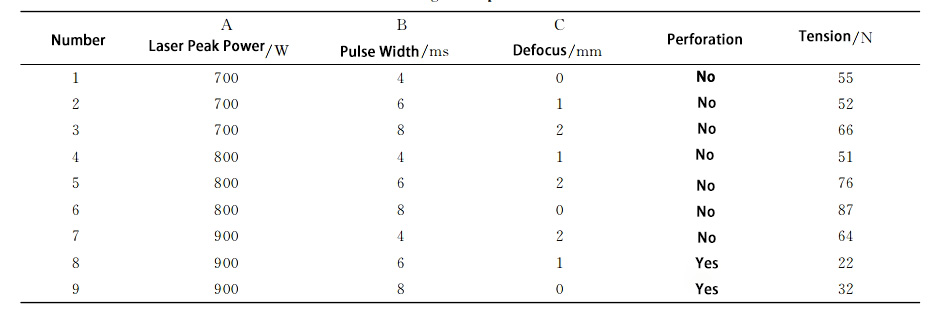

Three key parameters were varied:

Peak power (700W, 800W, 900W)

Pulse width (4 ms, 6 ms, 8 ms)

Defocus amount (0 mm, 1 mm, 2 mm)

Through orthogonal experiments, the optimal result was found at:

800W peak power

8 ms pulse width

0 mm defocus

This combination achieved the highest tensile strength of 87 N with no defects.

Tab.1 Orthogonal experimental results

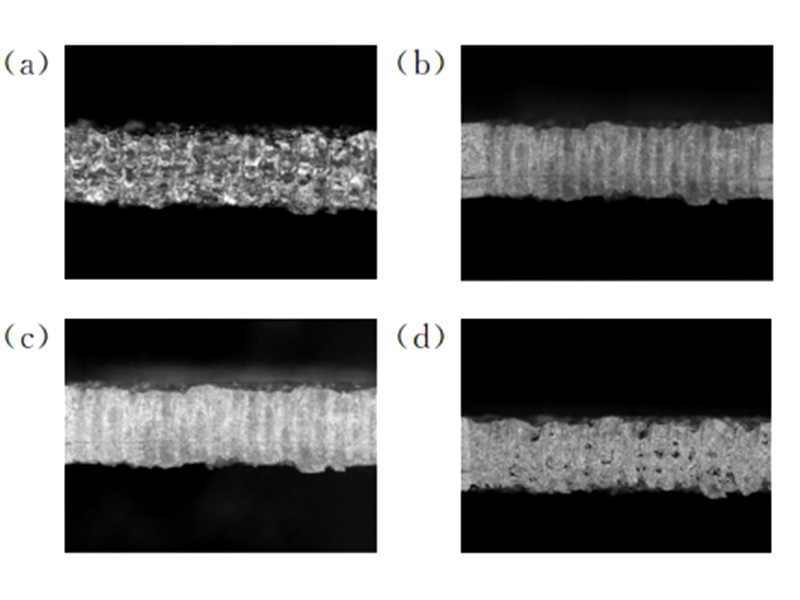

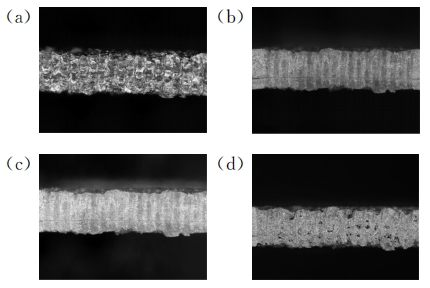

Samples were cross-sectioned and etched to observe fusion quality:

Lower power settings resulted in insufficient penetration.

Excessive power caused voids and porosity due to copper vaporization.

Optimal parameters produced uniform fusion zones with deep penetration and no pores.

Fig.3 Cross section of welding spots

(a) Experiments 1 and 2 (b) Experiments 3, 4, 5, and 7 (c) Experiment 6 (d) Experiments 8 and 9

The welding sequence significantly impacts post-weld deformation. Three sequences were compared:

Left-to-right → Deformation: 0.3 mm

Alternating (zigzag) → Deformation: 0.3 mm

Center-outward → Deformation: 0.1 mm (minimal)

Starting from the center and moving outward helps dissipate heat evenly, reducing thermal stress buildup.

Fig.4 Sequence of welding spots

(a) Solder from left to right (b) Solder one spot at a time from left to right (c) Solder from inside to outside

This study shows that direct laser welding of copper is feasible using a high-quality, single-mode quasi-continuous fiber laser. With careful parameter optimization and weld sequence planning, strong and stable joints can be achieved without pre-treatment or surface modifications.

Key takeaways:

High beam quality helps overcome reflectivity.

Clustered spots improve fusion and strength.

Deformation can be controlled with strategic weld paths.

This research offers practical value for industries seeking efficient and precise welding solutions for copper, such as electronics, batteries, and thermal devices.

Feb 5, 2026

카트는 현재 비어 있습니다..