카트는 현재 비어 있습니다..

In fields such as industrial manufacturing, cultural relic restoration, and ship maintenance, laser cleaning is gradually replacing traditional processes like chemical cleaning and mechanical grinding due to its efficiency, environmental friendliness, and non-destructive characteristics. The core support behind this technology is the rapid development of high-power fiber lasers. As the "heart" of laser cleaning equipment, high-power fiber lasers not only determine cleaning efficiency and effectiveness but also drive the upgrading of laser cleaning technology towards large-scale and refined applications. Why can it become the core driving force in the laser cleaning industry, and what key technological breakthroughs lie behind it?

Many people are curious about the principle of laser cleaning, and its core lies in the dual effect of "photothermal effect + non-contact stripping." The laser beam emitted by a high-power fiber laser has the characteristics of high energy density and high directionality. When focused, it can accurately act on the surface of contaminants (such as rust, oil stains, and oxide layers). After absorbing laser energy, the contaminants rapidly heat up, vaporize, or expand, generating an instantaneous impact force in an extremely short time to separate from the substrate surface. However, the substrate absorbs very little laser energy and will not be damaged.

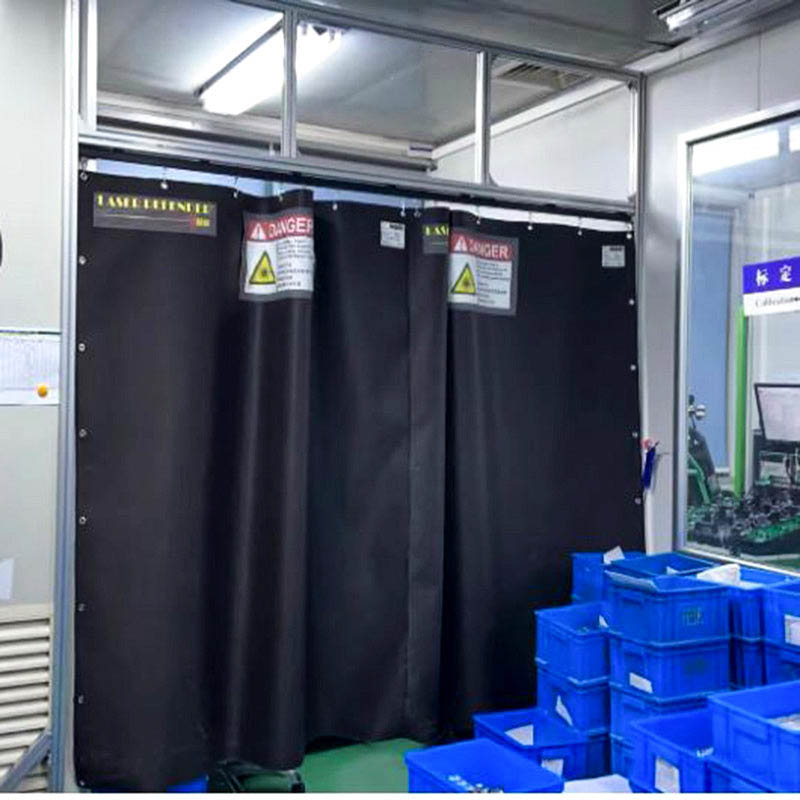

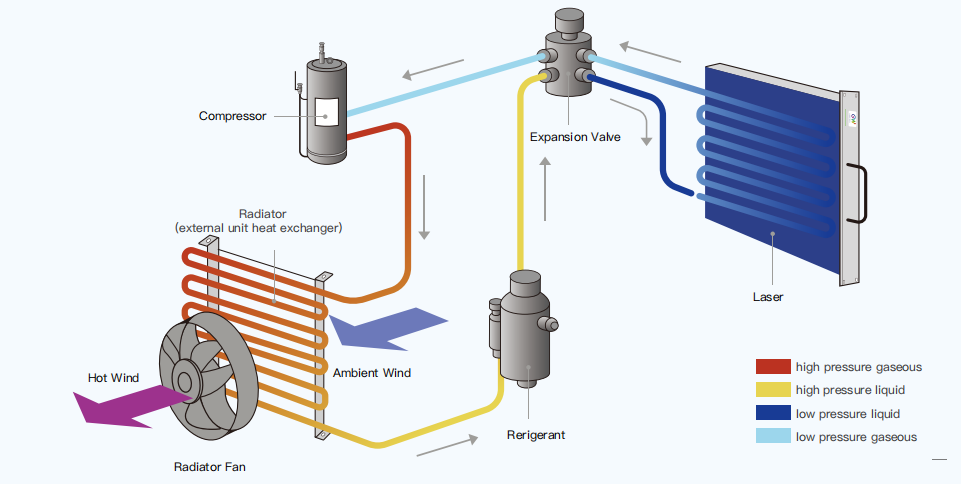

The advantages of this cleaning method are inseparable from the technical characteristics of high-power fiber lasers: fiber lasers have excellent output beam quality, with a beam quality factor M2 close to the diffraction limit (about 1.1), enabling refined cleaning for sensitive scenarios such as precision components and cultural relics; the output power can be flexibly adjusted, ranging from kilowatt to multi-kilowatt levels, which can not only quickly clean thick rust layers on large ship decks but also carefully remove dust on the surface of electronic components; the fiber transmission feature allows the laser head to move flexibly, adapting to the cleaning needs of complex-shaped workpieces and solving the dead corners that traditional cleaning is difficult to reach.

Compared with other types of lasers (such as CO₂ lasers and pulsed Nd:YAG lasers), high-power fiber lasers show irreplaceable advantages in laser cleaning scenarios. Firstly, in terms of efficiency and energy consumption, the electro-optical conversion efficiency of fiber lasers can reach more than 80%, much higher than traditional lasers. Under the same cleaning task, they have lower energy consumption and faster speed. For example, when cleaning rust of the same area, the efficiency of fiber laser cleaning machines is 3-5 times that of chemical cleaning.

Secondly, in terms of stability and service life, fiber lasers have a compact structure and no mechanical vibration. The core components have a service life of tens of thousands of hours, and they have strong anti-interference ability, which can adapt to the complex environment of industrial workshops and reduce equipment maintenance costs; while traditional lasers often have problems such as large size, high failure rate, and frequent maintenance. In addition, the wavelength range of fiber lasers (mostly 1060-1080nm) has higher absorption efficiency for common contaminants, and causes minimal damage to metal substrates, making them especially suitable for scenarios requiring high surface precision, such as the cleaning of aerospace components and precision molds.

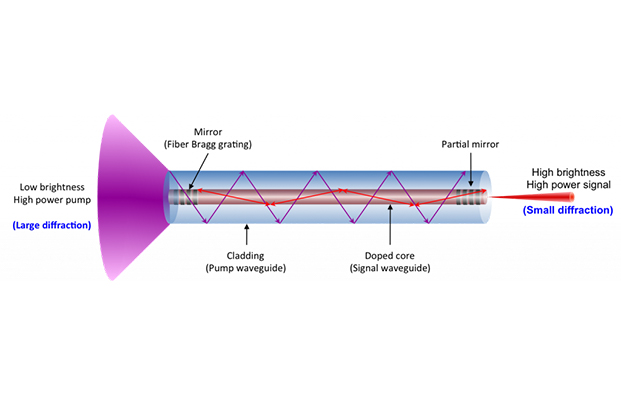

The large-scale application of the laser cleaning industry is inseparable from the key technological breakthroughs of high-power fiber lasers. Among them, large-mode-area fiber technology is one of the cores. By increasing the fiber core diameter, it not only ensures uniform energy distribution during high-power output but also reduces the power density inside the fiber, avoiding the impact of nonlinear effects (such as stimulated Raman scattering), making laser output more stable and the cleaning process more controllable. Currently, the core diameter of mainstream large-mode-area fibers has reached 20-40μm, supporting stable output at the multi-kilowatt level.

The optimization of fiber Bragg grating technology also plays an important role. As the core component of the laser resonator, the reflection bandwidth and reflectivity of fiber Bragg gratings directly affect the stability of laser output. Studies have shown that using a high-reflection grating with a 3nm reflection bandwidth can effectively avoid power leakage caused by laser spectral broadening under high power, making laser energy more concentrated and cleaning efficiency improved by more than 15%. In addition, the upgrading of key components such as cladding mode strippers and fiber combiners has further improved the power tolerance and energy transmission efficiency of lasers, providing a reliable guarantee for high-power laser cleaning.

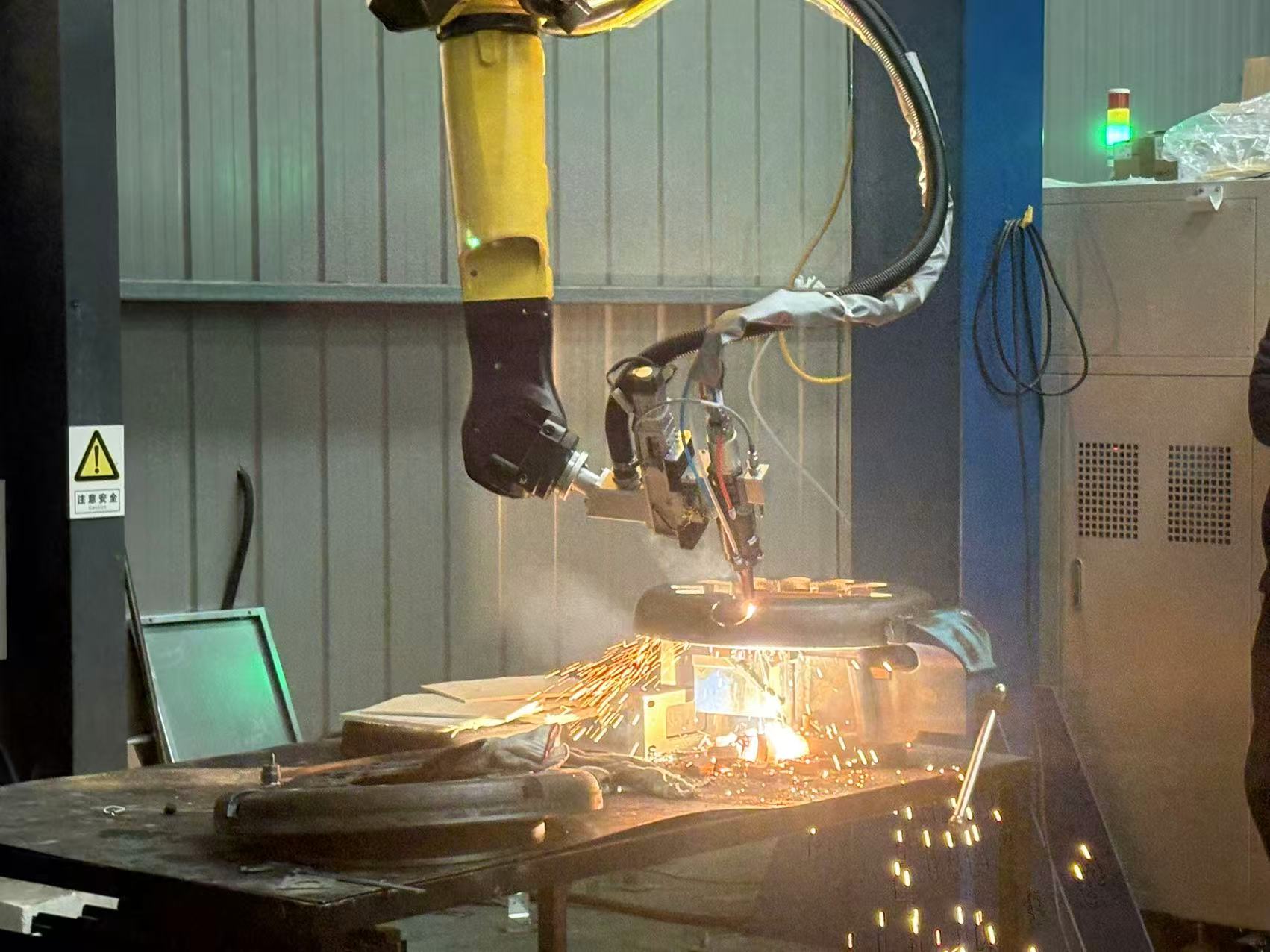

Today, high-power fiber laser cleaning has penetrated into various fields, becoming an environmentally friendly and efficient cleaning solution. In the field of industrial manufacturing, it can be used for oil stain cleaning of auto parts, residual material cleaning of mechanical molds, and rust removal of steel structures. After cleaning, the surface can directly enter the next process without secondary treatment; in the field of cultural relic restoration, low-power adjustable fiber lasers can accurately remove dust and oxide layers on the surface of cultural relics without damaging the cultural relics themselves, becoming an important tool for cultural relic protection in museums.

In ship and marine engineering, high-power fiber laser cleaning machines can efficiently clean marine biological attachments, rust, and coatings on the hull surface. Compared with traditional grinding methods, they not only improve efficiency several times but also avoid seawater pollution; in the field of electronic appliances, they can finely remove oil stains and solder residues on the surface of circuit boards and chips, ensuring the performance stability of electronic components. With the gradual reduction in the cost of high-power fiber lasers, laser cleaning is expanding from high-end industrial applications to civilian fields, with broad prospects in the future.

Feb 5, 2026

카트는 현재 비어 있습니다..